What is a Cooling Tower?

All cooling towers operate on the principle of evaporative cooling. They remove unwanted heat from one place and reject it to maintain a cool source of water for different types of processes. They are used to cool spaces in manufacturing facilities, where heat generating equipment such as lasers are commonly used, and as a source of comfort cooling in the HVAC industry. Many cooling towers are installed outdoors, but there are some scenarios where an indoor installation can be utilized as well. While the up-front cost of a cooling tower installation can be high, the efficiency and minimal cooling tower repair costs make these an outstanding long-term option for many buildings.

How Do Cooling Towers Work?

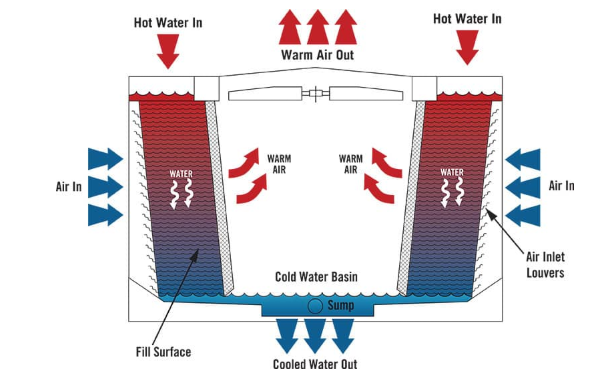

A cooling tower is a large enclosure that contains what is referred to as a “fill”. The fill is a plastic product that is essential in the evaporative process of the tower. As the rejected warm water flows over this fill, it is evaporated into the air either by natural draft or (in most cases) via an electric fan blowing across the fill. This fan can be either forced or induced drafted.

The most common design seen in our area uses a forced draft fan setup. The forced draft fan is installed in the base of the tower and pushes the air over the fill and out the top of the tower. The induced draft fan uses a slightly different draw-through method. The fan is located at the top of the cooling tower and draws the air through the fill. Induced Draft towers are known to have significant savings on energy compared to Forced Draft towers, but with the current availability of variable frequency drive motors, you can gain significant energy savings from either setup.

Is a Cooling Tower Right for You?

While we could go on for hours about Cooling Towers, we wanted to present this article as a short primer on the general operation of this equipment. If you are interested in learning more, need a cooling tower repair, cooling tower replacement, or would like to explore installing one for your facility, please contact our team to further discuss. We can be reached at info@controlairsystems.com, or over the phone at 781-365-0222.